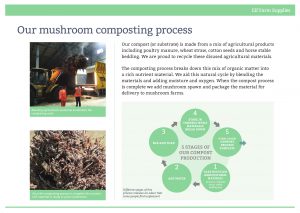

Elf Farm Supplies produces mushroom compost (substrate). Our mushroom compost is manufactured from recycled agricultural materials, including wheaten straw, poultry manure, stable bedding, gypsum and other nitrogen rich products, which are combined with a well-engineered environment to produce a high quality product.

The compost production process

Compost production is a four stage process, which involves:

Pre-wet

- Straw bales are pre-wet to initiate the composting process

- Straw bales and other ingredients are transfered and blended on a production conveyor line and transported to a Bale Wetting bunker.

- Re-blending occurs by removing product from bunker/s and adding back into another bunker, via hopper/conveyor production line, whilst recycled water and other raw materials are continuously added;

Phase 1

- Fresh air is supplied underneath the bunkers to control compost temperatures

- The compost is blended a number of times and has water added to adjust its moisture content.

Phase 2

Both phase 2 and 3 of the compost process involves the compost being stored in tunnels which are designed to enable the circulation of air through the compost.

- Phase one compost is loaded into tunnels using a cassette filler which is a system of conveyors that extend into the tunnels

- The compost is placed on top of a pulling net, which enables subsequent removal from the tunnel

- Each tunnel holds up to 200 tonnes of phase one compost

- The phase 2 process is computer controlled

- Each tunnel has a dedicated air intake and fan system. Air is passed through a series of filters to remove particles.

- Phase 2 and 3 is serviced with chillers and cooling towers

- Compost is initially levelled to a consistent temperature then heated to pasteurise the compost. Phase two is designed to kill unwanted pathogens and to create an ideal nutrient and bio-logical medium for mycelium development (from which mushrooms grow)

Phase 3

After phase 2 is complete, the compost is cooled down, and mushroom spawn is added to the compost (phase 3). This operation is undertaken following intensive cleaning and disinfecting. It is imperative that “sterile” conditions are created to prevent infection of the compost with unwanted pathogens that can impede mushroom growth.

- Phase 2 material is removed from the tunnel using a pulling winch, inoculated with spawn and returned to another tunnel using a cassette filler.

- The phase 3 process is fully computer controlled to create environmental and biological conditions that maximise mushroom mycelium development.

- At the end of this process, phase three material is removed from the tunnels using a pulling winch, loading the compost onto trucks for bulk shipment.

Phase 3 blocks

At the end of the process, some of the phase 3 compost is then manufactured into blocks for shipment.

The length of the process from commencement of pre-wet to ship out is approximately six to seven weeks. Mushroom harvesting then commences a further two weeks after delivery of the material to the farm.

Last Updated June 2020, RT.